Oil & Gas Well Testing

Discover the benefits of our fully customizable oil and gas well testing packages. With years of proven reliability, we are your trusted partner in obtaining the essential well test data you need to unlock the full potential of your oil and gas reservoirs.

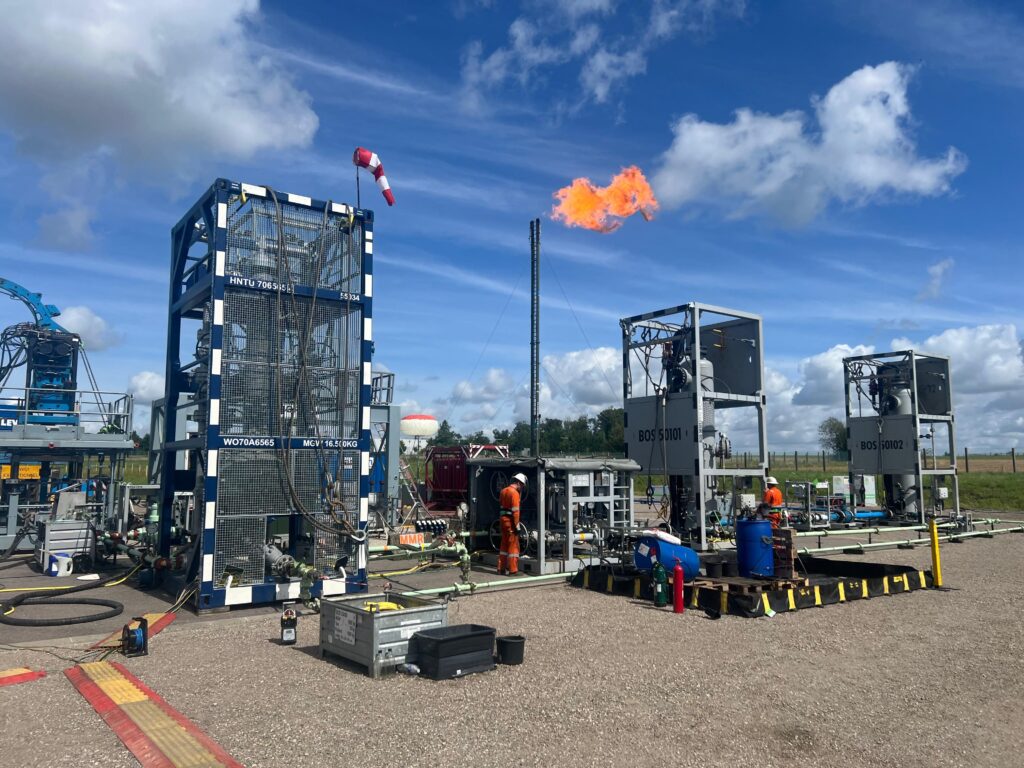

We offer well testing solutions for exploration, appraisal, and development wells. Whether your primary product is natural gas or crude oil, we have the solution for you. The well test process is carried out using state-of-the-art equipment, including sand filters, desanders, three-phase separators, heater exchangers, choke manifolds, LP separators, surge tanks, KO vessels, and flare stacks or clean enclosed burners. This equipment meets the latest standards and is equipped with advanced safety systems and technologies, such as PSV/PRVs, pressure pilots, high and low-level switches, and ESD systems, to ensure a safe process.

Our team of highly skilled engineers, competent field supervisors, technicians, and data acquisition engineers ensures accurate measurements and concise reporting of your well’s parameters—all conducted in a safe, efficient manner with respect for the environment! We offer a comprehensive range of oil and gas well testing solutions, including well clean-up/clean-outs, multi rate tests, and return handling packages.

Clean-Up and Flowback Operations

The well clean-up or flowback process, often combined with well testing, removes contaminants such as drilling mud, sand, brines, and stimulation fluids from the flow stream. To protect production facilities from potential damage, the well is processed through our temporary well testing equipment, including cyclone desanders, sand filters, and two or three phase separators.

These systems handle contaminants more efficiently and flexibly than standard production facilities. Clean-outs are typically performed using coiled tubing or hydraulic workover equipment, which circulates solids from the well to the surface. During this proces, the solid HUD can be deepened or plugs are milled and removed with the aid of specialized fluids, nitrogen, and gels that assist in lifting and circulating. Our cyclone desanders and sand filters effectively remove solids while our three-phase separators manage the separation of fluids. Nitrogen and gas are safely directed to flare stacks through KO (knockout) vessels, and the fluids are carefully measured and stored in designated tanks. Meanwhile, we collect valuable data on well performance to help optimize the well testing process.

Surface Well-Testing

We recognize the importance of accurate well test data for effectively managing hydrocarbon assets. Surface well testing is the definitive method for assessing reservoir potential, from exploration to appraisal wells. With our extensive fleet of advanced equipment and experienced team, we are committed to delivering reliable, high-quality results.

Multi Rate Test

Once the well is cleaned up, we can begin the well testing process, including, for example, the multi rate test. During this test, the well flow is controlled at multiple rates using our double block choke manifold. If needed, flow can pass through our heat exchanger to prevent hydrate formation or assist with fluid separation and foaming oil.

In our three-phase separator, water, oil, and gas are separated, quantities measured, and logged. Gas flow is measured using a precise Coriolis meter, then directed through a knockout vessel and burned efficiently by our silent flare stacks or returned to production.

Water and oil are measured using industry-standard turbine flow meters. Our surge tank can be used for second-stage separation, meter calibration, and establishing shrinkage factors. From there, fluids are pumped to storage tanks for processing or disposal.

At the end of the test, the well is shut in at the choke manifold, and a pressure buildup is monitored. This provides valuable data on reservoir boundaries, permeability, and skin factor. Strategically placed transmitters throughout the system log and display the data. Our data acquisition engineer compiles a detailed report, which is presented to the client for analysis.

Return Handling Packages

Our return handling equipment can be customized and utilized for a variety of demanding jobs and challenging circumstances, including P&A support, frac flowback, pigging jobs, clean-outs, and (underbalanced) drilling.

We provide solids separation with our cyclone desanders and dual pot sand filters, and fluid separation with a wide range of separators, including our low and high-pressure separators or our two- and three-phase separators. Degassers can also be employed if gases are anticipated in high-volume liquid streams.

Ready to unlock the full potential of your oil and gas resources? Our well testing services provide the data and insights you need for the long-term success of your projects. Contact us today to discover how we can help you achieve your goals.

Equipped for Solutions: Oil & Gas

Elevate your projects with Bakker Oilfield Supply, the partner for high-quality products and services in the sustainable energy and oil and gas industries.